Revoseal JP-2

Description:

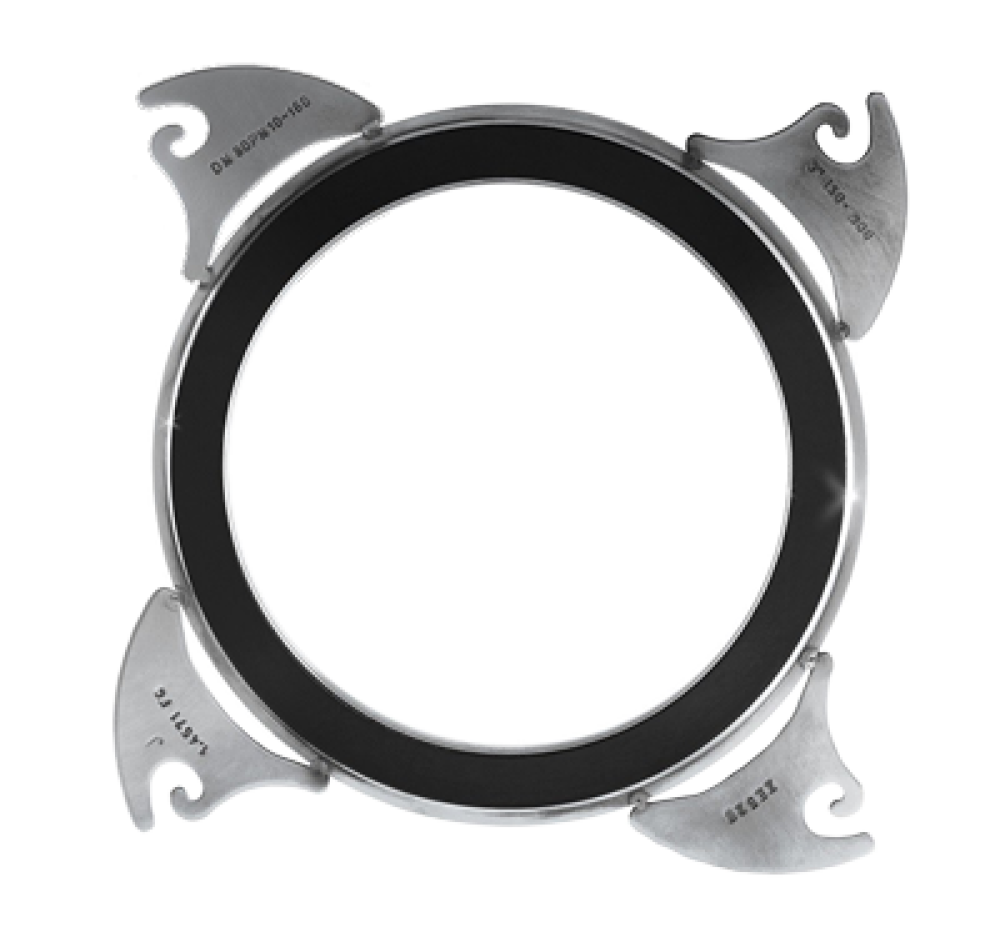

The internationally patented geometry of outer and inner cogging completely encapsulates the GRAPHITE or PTFE layers.

The tooth geometry has been calculated in such a way that even at using low quality bolts an ideal compression of the graphite layers and a double metallic sealing can be achieved. Therefore, Jungtec JP (encapsulated flat proile gaskets) combine the advantages of metal and composite materials in an ideal way.

- Service temperature up to 1000 °C using graphite layers SGL Carbon

- Measured leakage rate less than 10exp-11 mbar.l/m.s

- Resistance to oxidation and thermal cycling till 1500 lbs rating

More Information

Contact us for more information

-

TECHNICAL FEATURES

- Temperature: -200 °C + 1000 °C (dependent on the carrier material)

- Specific loss rate: 1x 10-11 mbar x l/ (m x s) (acc.to Ta-Luft VDI2440)

- Pressure: to 400 bar (1,500 lbs) m factor: 1.0

- Qs max: 500 MPa

- Qs min: 200 MPa

- The effective gasket width: can be adapted in order to achieve optimum sealability in accordance to the Technical Instructions on Air Quality Control (TA-Luft), VDI 2290 according to DIN EN 1591

- Total thickness: 4.2 mm (additional thicknesses on request)

- Material available: AISI 304, AISI 304L, AISI 316/L/Ti, , AISI 321, AISI 347 (alloys on request)

- JP-2 profiles reproduce the tongue and groove principle

- Lowest leakage rates of all gaskets available on the market

- Fire Safe Certificate according to API 607 (also for PTFE), blow-out resistance according to VDI 2200 and Ta-Luft approved acc. to VDI2440

Our Catalogs