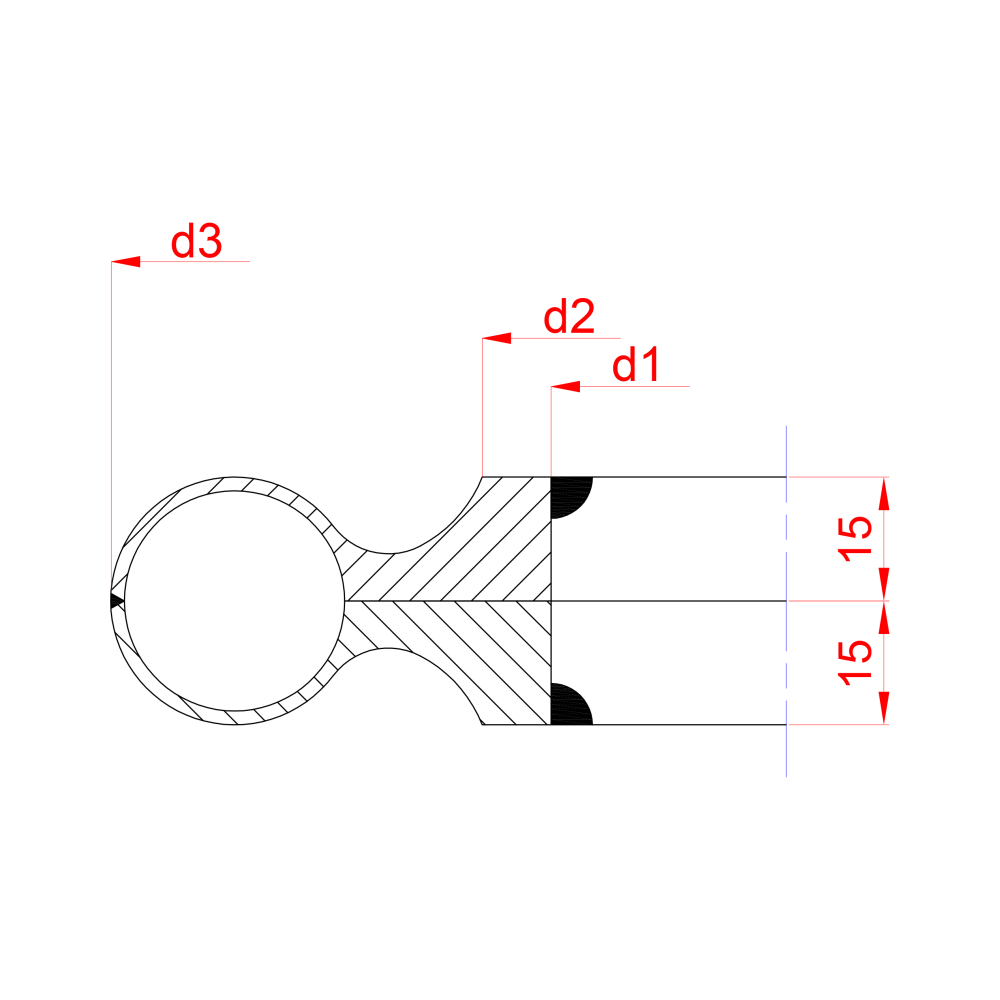

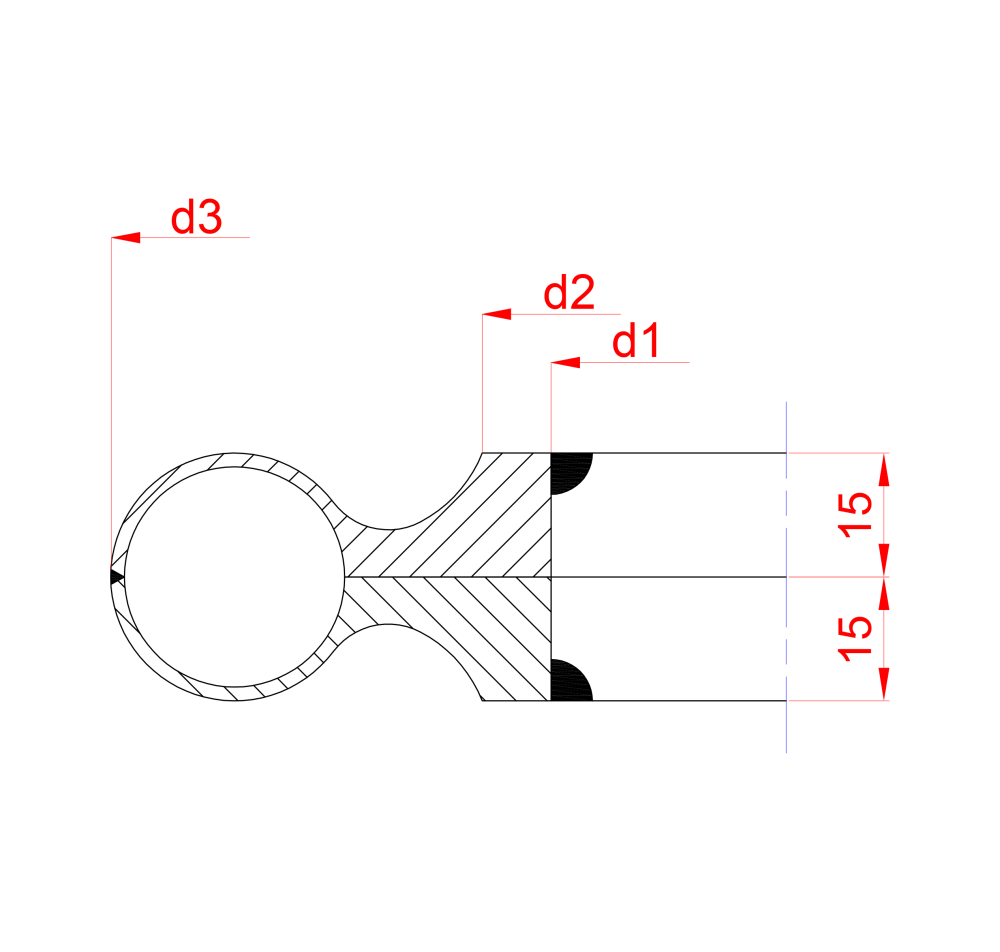

CF 8004

Description:

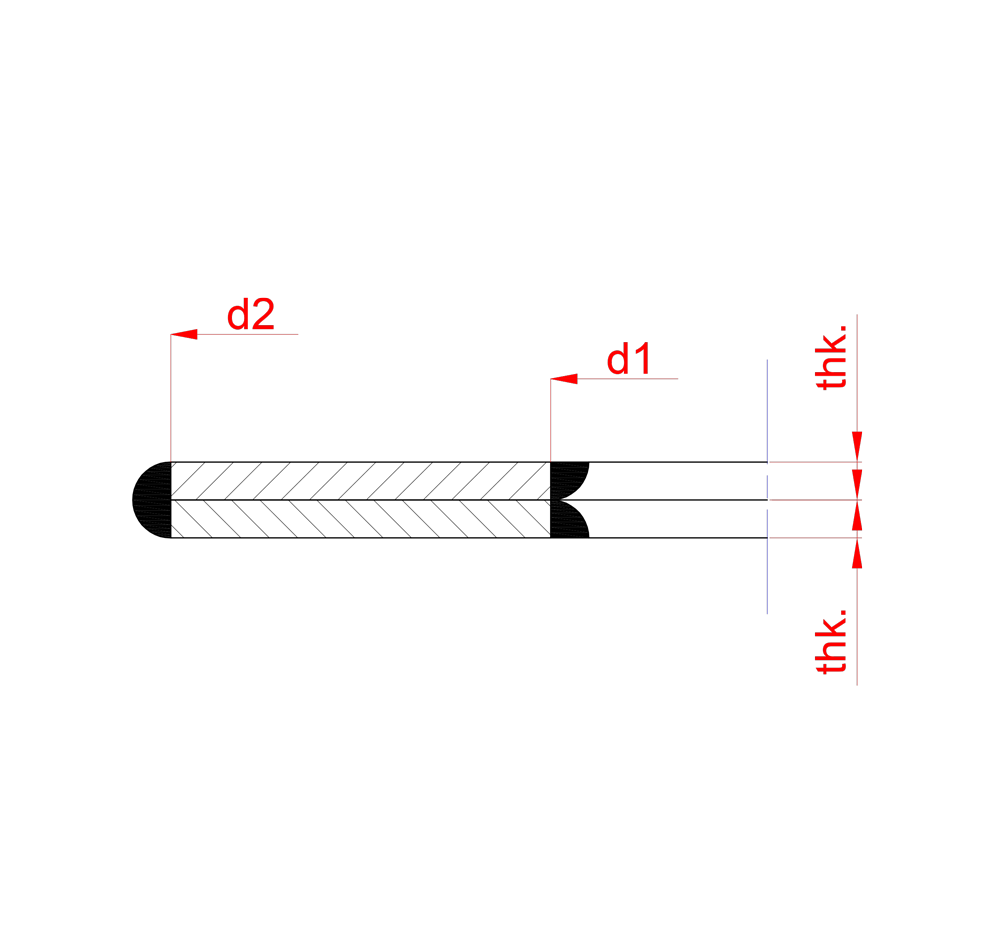

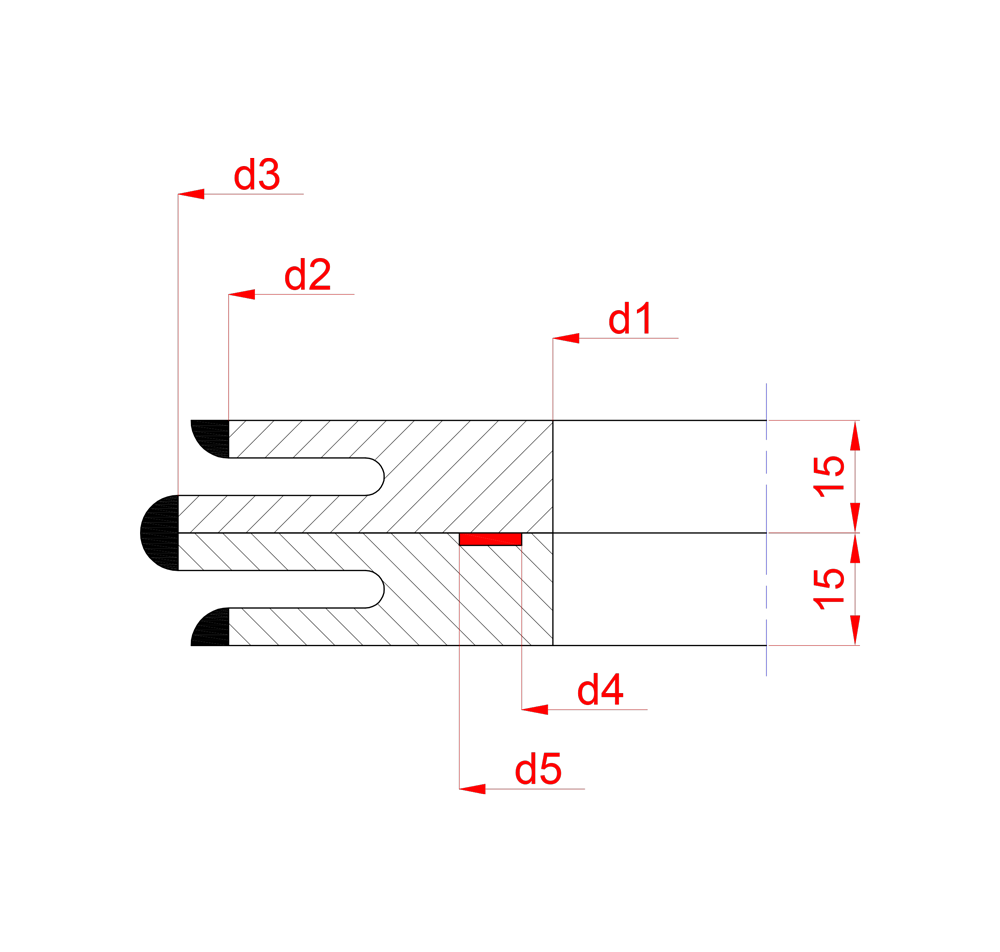

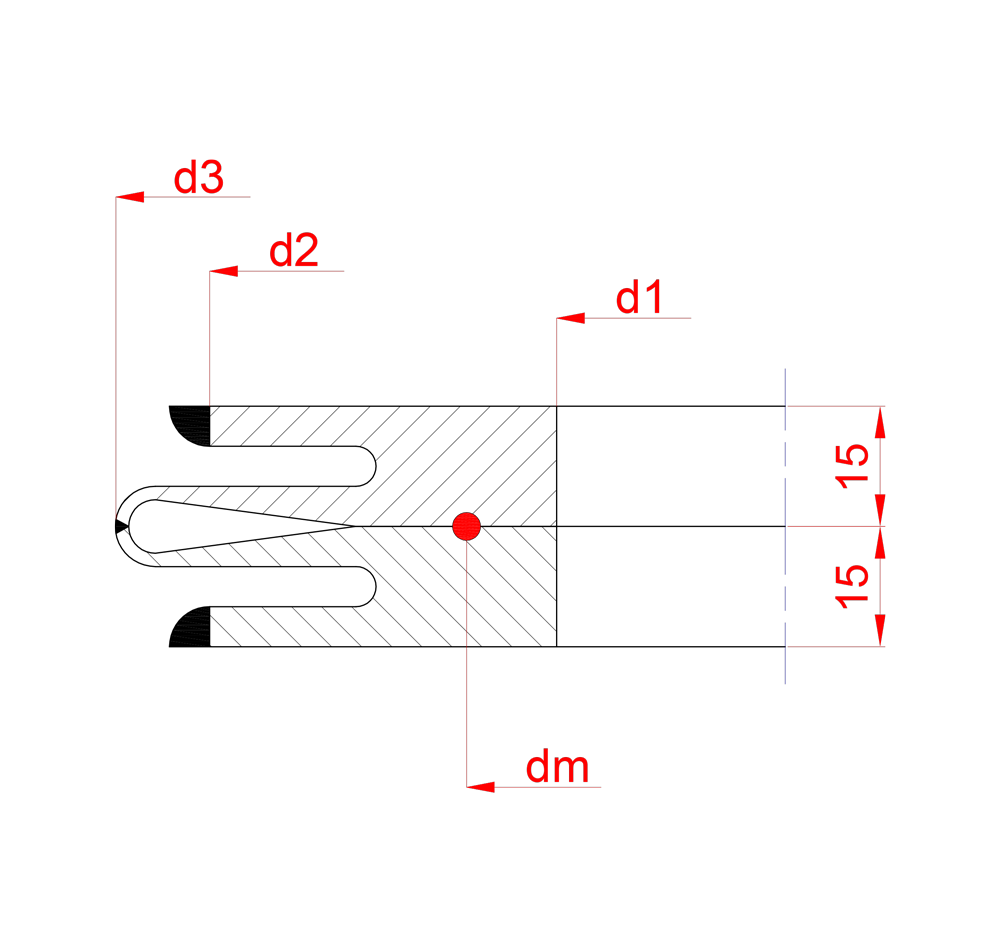

CF8000 series LIP SEAL gaskets (also called weld rings) are mainly used in pressure equipment, where a high degree of sealing is required (eg Ta - Luft) and a stable seal over time in the event of deformation and / or dilation during appliance operation.Based on the movements of the flanges during operation (axial and / or transverse movement), the most suitable profile is selected.

If the execution of the hydraulic test is necessary, the 8000 series gaskets can be supplied with a special internal seal (o-ring or the execution of the test without having to weld the LIP SEAL.

- Ideal for zero emission installations

- Versatility in selecting the type

- Wide choice of structural conformations and types of alloys

- Ideal for the Oil & Gas sector

CF8004, unlike the CF8001, CF8002 and CF8003, guarantees greater adaptability in case of significant movements and deformations of the flanged coupling.

It is particularly suitable for use on high temperature applications or in the event of significant temperature changes.

Inside it creates a seal (o-ring or camprofile) which is used in the event of a hydraulic test of the device.

It is mainly used on large diameters.

The surface finish of the flanges must be between 25 - 50 μm.

More Information

Contact us for more information

-

TECHNICAL FEATURES

- Typologies available ttpe IBC per flange RF | Flanges Tongue & Grove | Flat flanges | A design

- Applied standards of construction ASME Code 16.20; B16.47; API DIN 2696; DIN 2695

- Temperature range ( °C) -200/+750 550*

- Max pressure ( bar) 1500 350

- Compression resistance (Mpa) 650 400

Materials Mx temperature AISI 304; 316; 316L; 316Ti; 321; 347 550 °C Alloy 400; 600; 625; 800; 825 600 – 750 °C Hastelloy C276; B2 450 °C Titanio Gr.2 350 °C

Material hardness

Materials Max hardness Brinell Rockwell B Soft Iron 90 56 Low Carbon Steel 120 68 F5 130 72 AISI 304 160 83 AISI 316 160 83 AISI 321 160 83 AISI 347 160 83 AISI 410 170 170

Our Catalogs